Common Methods of Thermocouple Calibration

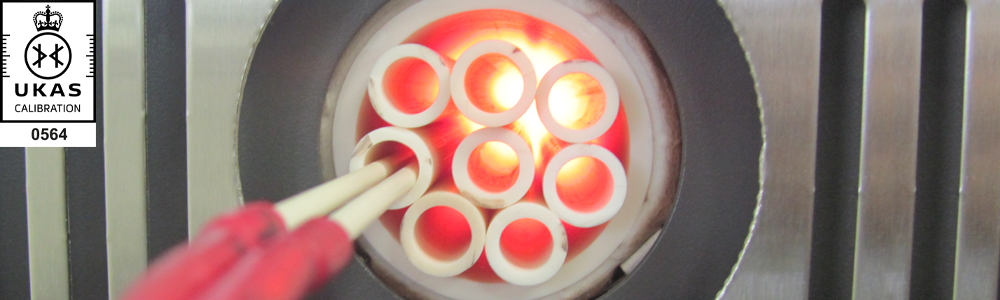

UKAS Accredited Thermocouple and RTD Pt100 Calibration

Thermocouples are widely used in industrial and scientific applications to measure temperature. However, whilst thermocouples are robust temperature sensors that cover a wide temperature range, the voltage they generate can be prone to drift over time and through exposure to certain atmospheres. Because thermocouples and associated equipment are usually critical to the processes they monitor, regular calibration, where the thermocouple's output is compared to a known reference temperature and making necessary adjustments, is recommended to monitor any potential drift and to ensure the continued efficacy of the sensor. For some applications, for example those that see a large cycling of temperatures, calibration should be performed frequently.

Why calibrate thermocouples?

Calibrating a thermocouple probe is essential for several reasons:

-

Accuracy: Over time, thermocouples can drift and lose their accuracy. Regular calibration helps to maintain the precision of temperature measurements.

Quality Control: Many industrial processes rely on precise temperature control. Calibration ensures that the thermocouples used in these processes provide accurate data.

-

Compliance: In some industries, regulatory standards require specific periodic calibration to maintain compliance with quality and safety standards.

-

Preventing Errors: Incorrect temperature measurements can lead to costly errors and product defects. Calibration can help prevent these issues.

What is thermocouple calibration?

A thermocouple is a simple but reliable device widely used for temperature measurement in industrial and scientific applications. Thermocouples produce a voltage corresponding to a difference in temperature between a measuring junction and a reference junction. The process of thermocouple calibration involves comparing the thermocouple output measurement against a known reference standard at a known temperature.

A thermocouple calibrator usually refers to a device that simulates a thermocouple voltage. Thermocouple calibrators are used to calibrate thermocouple instruments, transmitters and data acquisition equipment. In this article, we are concerned mainly with the calibration of the thermocouple probe / sensor rather than instrumentation, although we do offer accurate instrument calibration and system calibrations (probe and instrument together) in our laboratory.

How to calibrate a thermocouple probe

There are a few ways to calibrate a thermocouple probe. The most accurate thermocouple calibration is achieved is by using a Fixed Point cell where the thermocouple's output is measured against a number of fixed points along the International Temperature Scale developed in 1990 ITS-90 at the fixed point transition of various metals along the scale. Whilst this is the most accurate method of calibration, the temperatures are not always convenient or useful in practical terms for the intended use of the thermocouple. For example, the melting point of gallium is 29.7646 °C which is not a temperature most thermocouples will be used at. However, the triple point of water (0.01ºC) is used quite regularly in our laboratory.

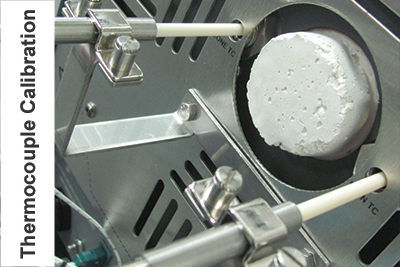

By far the most popular type of calibration procedure our lab technicians perform is the comparison method where the test sensor is placed in a stirred liquid bath, furnace / oven or dry block calibrators at a specified temperature and it's output is compared against a known reference thermocouple or RTD Pt100 thermometer placed alongside the test thermocouple in the chamber. The sensor can thus be calibrated at virtually any temperature required. Our laboratory can calibrate sensors from liquid nitrogen right up to 1590 degrees celsius as shown in the measurement uncertainty data below.

How often should I calibrate my thermocouple?

The biggest problem for a thermocouple is drift which is caused by temperature cycling and environmental conditions causing contamination. The amount of cycling and contamination will depend on the application. In practice, we would suggest that thermocouple calibration is performed once a year although this should be reduced for thermocouples in use in arduous conditions. Our experienced engineers are available to offer advice either by phone, email or using Live Chat.

What are the risks of not calibrating a thermocouple?

As mentioned above, thermocouples drift over time leading to measurement errors and without regular calibration they may give a reading that is either a bit higher or lower than the actual temperature and so lead to measurement inaccuracy. Having a calibrated thermocouple means that instrumentation can be offset according to the calibration results.

Can thermocouple wire be calibrated?

Yes, if you are making simple thermocouples from a reel of thermocouple wire, then we can issue a calibration for the reel of thermocouple cable used.

Specialists in Thermocouple and RTD (Pt100) Calibration

TC Ltd specialise in thermocouple calibration and RTD calibration and we are proud to offer a wide variety of industry sectors with accurate and traceable In-House or UKAS (United Kingdom Accreditation Service) accredited calibration. This service is applicable for thermocouples, RTD sensors, instrumentation and cables under the scope of ISO/IEC 17025 & ISO 9001, all within our fully UKAS accredited calibration laboratory.

With the drive towards higher product quality standards and energy efficiency, end users are demanding more certainty and traceability from the products they purchase. A speedy, economical and reliable calibration service is provided in all respects. Significant investment has resulted in our UKAS accredited laboratory offering a world class service in terms of both CMC (Calibration and Measurement Capability) and volume throughput.

For more information on thermocouple and RTD calibration, please contact one of our experienced engineers on 01895 252222 or by using the Live Chat.

UKAS or Traceable In-House Certification of Thermocouples and RTD Sensors

Traceable In-house or UKAS accredited calibration is available for Base and Noble metal thermocouples and RTD sensors (Pt100) performed within our fully accredited laboratory.

Calibration is usually by comparison, traceable to National Physical Laboratory primary standards, against SPRTs or Type R reference thermocouples from -100 to +1590ºC. Fixed point calibration also available at -196ºC.

Temperature Calibrators

K Type Thermocouple 2-in-1 Simulator and Thermometer Simulation and measurement of K Type Thermocouples.

High Accuracy Temperature and Process Calibrator

Simulation and measurement of K Type Thermocouples.

High Accuracy Temperature and Process Calibrator

Simultaneously measure and simulate ten types of thermocouples or seven resistance thermometers.

Portable Dry Block Calibrator

Simultaneously measure and simulate ten types of thermocouples or seven resistance thermometers.

Portable Dry Block Calibrator

This dry block calibrator is compact and easy to use, making it suitable for use on site without the need for heavy, expensive equipment.

Dry Block

This dry block calibrator is compact and easy to use, making it suitable for use on site without the need for heavy, expensive equipment.

Dry Block Calibrator

Generate true reference temperatures to facilitate the calibration of temperature sensors and systems.

Generate true reference temperatures to facilitate the calibration of temperature sensors and systems.

Measurement Uncertainty Data for Thermocouple Calibration and RTD Calibration

Our uncertainty of measurement is listed below for various ranges for thermocouples and RTD sensors:

Type of Sensor |

Range | Calibration and Measurement Capability (CMC) Expressed as an Expanded Uncertainty |

|---|---|---|

| Resistance Thermometers | Liquid nitrogen (-196ºC) Triple point of water (0.01ºC) -100ºC to -30ºC -30ºC to + 20ºC 20ºC to 90ºC 90ºC to 200ºC 200ºC to 400ºC 400ºC to 620ºC |

0.060ºC 0.050ºC 0.60ºC 0.20ºC 0.20ºC 0.20ºC 0.40ºC 0.40ºC |

| Thermocouples - Noble Metal |

20ºC to 200ºC 200ºC to 400ºC 400ºC to 620ºC 620ºC to 1100ºC 1100ºC to 1200ºC 1200ºC to 1330C 1330ºC to 1590ºC |

0.90ºC 0.90ºC 0.90ºC 1.70ºC 1.70ºC 2.70ºC 3.30ºC |

| Thermocouples - Base Metal |

Liquid nitrogen (-196ºC) -100ºC to -30ºC -30ºC to + 200ºC 200ºC to 400ºC 400ºC to 620ºC 620ºC to 1100ºC 1100ºC to 1200ºC 1200ºC to 1330ºC |

0.35ºC 2.60ºC |

International and Industry Specific Standards

Calibration can be performed to meet the requirements of most international and industry specific standards including AMS2750G, IEC 60584-1, IEC 60571, ASTM E220, ANSI MC 96.1, ASTM E235, ASTM E608, ASTM E839, GDCD16 & BAC5621K. We can also perform batch and reel calibration on selected material to ensure the best results possible when adhering to these strict standards.

Other Calibration

Electrical simulation for precision instrumentation calibration. Surface measurement is also available as well as calibration of sensors and instrumentation together as a system.

International Calibration Bodies

NPL is a signatory to the CIPM MRA (Mutual Recognition Agreement) and as such results shown on our certificates can be considered as being traceable to all other NMIs (National Measurement Institutes) who are signatories to the MRA including NIST.

Conclusion

Thermocouple calibration is a crucial step in ensuring accurate temperature measurements in various applications. Regular calibration helps maintain the reliability and precision of thermocouples, reducing the risk of errors and improving product quality. By following the appropriate calibration methods and documenting the process, you can ensure that your thermocouples provide consistent and accurate temperature data.

For more information on thermocouple and RTD calibration, please contact one of our experienced engineers on 01895 252222 or by using the Live Chat.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia