What is a Thermowell? Flanged and Threaded Thermowells

for Thermocouples and RTD Sensors

What is a Thermowell?

Thermowells, sometimes called pockets or thermo-pockets, are a specialised protection tube or vessel designed to hold and to protect a thermocouple or rtd temperatue sensor against attack from the chemicals or harmful atmosphere of a process by encasing the temperature probe in a protective sheath.

They maintain the integrity of the process and also allow for temperature sensors to be removed for calibration or replacement without needing to drain the system. By providing a protective environment, they also reduce the risks of contamination and degradataion of the sensor thereby improving its longevity.

Styles of Thermowell Sheath

Thermowell sheaths are generally available either straight (parallel), which has the same diameter of sheath along the length of the thermowell. This basic style provides the sensor with protection against corrosion and contamination.

Stepped thermowells have a larger diameter at the top (near the process connection) which is then stepped down to a smaller diameter near the tip. This allows for a faster response to changes in temperature in the process.

Tapered thermowells are robust thermopockets which have a sheath diameter that gradually reduces over its length. As well as providing a fast response to temperature changes, tapered thermowells are often used where the process is running at a high velocity or flow rate as the installation of this design tends to reduce the vibration of the sensor.

Thermowell Products

ThreadedThermowells

A wide range of thermowells with an extensive selection of process connection threads

Flanged

A wide range of thermowells with an extensive selection of process connection threads

FlangedThermowells

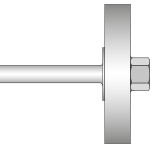

Solid drilled or fabricated pipe thermowells with a wide choice of flange sizes and types

Solid drilled or fabricated pipe thermowells with a wide choice of flange sizes and types

Materials for Thermowells

We offer a wide range of thermowell sheath materials designed for a wide range of applications:

Grade 316L Stainless Steel. Very good corrosion resistance throughout the operating temperature range. Suited to a wide range of industrial applications. Enjoys high ductility. Max. temperature: 800°C.

Grade 310 Stainless Steel. Good high temperature corrosion resistance and suitable for use in sulphur bearing atmospheres. 310 stainless steel has high oxidation resistance. Max. temperature: 1100°C.

Inconel 600. Used in severely corrosive atmospheres to elevated temperatures. Has good resistance to oxidation. Do not use in sulphur bearing atmospheres above 1020°F. Max. temperature: 1100°C.

Incoloy 800. Used in severely corrosive atmospheres to elevated temperatures. Enjoys a good resistance to oxidation and carburisation. Resistant to sulphur bearing atmospheres. Max. temperature 1100°C.

Incoloy 825. Highly resistant to corrosion and oxidising conditions. Particularly useful when used in acidic environments. Max. temperature: 1250°C.

Hastelloy 276. Excellent general corrosion resistance and good fabricability. Highly popular for chemical and petrochemical processing applications. Max. temperature: 1250°C.

Monel 400. Monel is particularly resistant to corrosion by seawater and has high strength and toughness over a wide temperature range. Max. temperature: 1250°C.

PTFE. A fluorocarbon based polymer, PTFE offers high chemical resistance, low friction and electrical and thermal insulation over a wider temperature range than most plastics. Perfect for protecting metals against acid attack. Max. temperature: 250°C.

Process Connection Types for Thermowells

Flanged Thermowells

We have two main types of process connection: either threaded or flanged to be welded. Flanges are manufactured in accordance with internationally recognised standards such as ANSI, DIN or JIS and are available in 1/2", 1+1/2" and 2" diameter with face types of either Flat, Raised, Ring Type Joint or Tri Clamp).

Thermowells with a Thread Connection

Our threaded thermowells are generally available with a 1/2", 3/4" or 1" BSPT process thread, although other thread sizes such as NPT may be specified if required. Socket weld connections are also available.

Insertion Length (Immersion Length)

The immersion length is the distance from the thread (below the thread start for a tapered thread type e.g. BSPT or below the hex for a parallel thread type) or the distance from the flange face to the tip of the thermowell.

If a thermocouple is used, then the length of the thermowell can be shorter than if an rtd sensor is used, due to the impact immersion depth has on temperature measurement for rtd sensors compared to thermocouples which are tip sensitive.

Whichever sensor is used the insertion length must be long enough to allow the temperature sensitive section of the sensor to extend fully into the process being measured.

We can also supply thermowells with a lag extension if required. Our engineeers are on hand to assist you and make recommendations based on a drawing or the type of sensor being used and the temperature range of the process. Further information is available in our Thermowell Datasheet.

Testing and Certification

We offer and range of testing and certification for all our thermowells including: ASME PTC 19.3 TW-2010 (wake frequency calculation), pressure testing, MTC's, X-Ray, dye penetration, full penetration weld and NACE MR0175 (hardness test). Please contact us for further information.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia