TC helps multinational Aerospace Component Manufacturer meet AMS2750 standards

Contents

Company Background

A multinational aerospace manufacturer approached us with concerns about failing System Accuracy Tests (SATs) on their heat treatment ovens. These failures had caused their AMS2750-compliant work to stop, leading to significant downtime and additional costs.

Challenges with Temperature Measurement

Despite having an excellent understanding AMS2750 requirements, the company faced two main issues:

- System Accuracy Test Failures: SATs frequently failed on two key ovens, causing downtime and labour intensive investigations.

- Costly Interruptions: Frequent retests required additional SAT sensors and prolonged the ovens' downtime.

- Space Constraints: The existing sensor placement made it difficult to align SAT sensors with primary control and recording sensors.

Ultimately, the manufacturer ceased AMS2750 work with the affected ovens, impacting their capacity and revenue.

Consultation Process

TC conducted an in-depth consultation to understand the challenges and the root cause was identified as:

- Misalignment of the SAT sensors with primary control sensors, resulting in inaccurate readings.

- Space limitations preventing proper sensor placement near control sensors.

By understanding the oven configuration and AMS2750 requirements, TC devised a practical solution tailored to the client's needs.

Proposed Thermocouple Solution

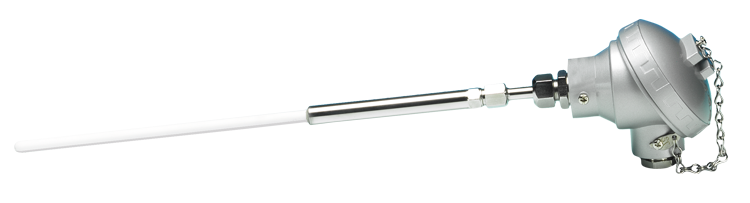

We recommended our Type 40S Industrial SAT Vacuum Furnace Thermocouples.

Key features included:

- Integrated Design: A SAT probe port (1.5mm or 2.0mm) within the same sheath as the control thermocouple.

- Precise Placement: Ensured the SAT probe aligned closely with the control thermocouple sensing tip for better accuracy.

- Streamlined Installation: A compact design overcame space constraints, eliminating the need for additional oven modifications.

This solution enabled accurate SAT readings, better monitoring of control sensors, and improved oven performance.

Conclusion and Results

The Type 40S thermocouples and new SAT sensors were installed, and subsequent SATs passed without issues. The results included:

- Restored Compliance: Both ovens resumed AMS2750 compliant operations.

- Increased Capacity: The manufacturer could take on more projects.

- Cost Savings: Reduced downtime and labour, avoiding additional equipment modifications.

The tailored solution improved performance and efficiency, increrasing the manufacturer’s capabilities in aerospace heat treatment.

Note: This solution resolved a specific challenge in a particular application. Every situation is different, and your needs may require a different approach. The suitability of any of our products for a particular application is ultimately for the purchaser to determine, as they are best positioned to make that judgment.

These case studies are shared to illustrate how our products have been used successfully, but final product selection should always be based on your specific application requirements, standards, and industry regulations. The suitability of any of our products for a particular application is entirely at the discretion of the purchaser as being the best judge for that particular application.

For application-specific advice, please contact us — one of our engineers will be happy to assist with technical guidance.

Further Reading

Learn more about AMS2750 approved thermocouples

Explore our range of thermocouples, cables and instrumentation which will meet all of your heat treatment requirements for SAT tests, temperature uniformity survey (TUS) tests and production work in AMS2750G approved furnaces and ovens.

See our range of thermocouples for demanding applications

Discover designs of thermocouples for use in diverse and challenging environments.

Why calibrate thermocouples in a UKAS Accredited Laboratory?

Understand the significance of calibration in achieving precise measurements.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia