TC's 'Reduced Shock' Pt100 temperature sensors excel in automotive engine test application

Contents

Background to Project

Temperature measurement is a crucial part of automotive engine design, manufacture and testing and with a vast number of components subjected to rigorous temperature tests, it is essential to have reliable and precise temperature sensors.

TC has a wealth of experience in designing and manufacturing temperature measurement systems for automotive applications, so when a major automotive manufacturer faced persistent issues with their temperature sensors, they approached us to help find a solution.

Customer Pain Points

The customer was using expensive 1/10 DIN Pt100 temperature sensors during engine exhaust manifold tests but experienced frequent sensor failures. This not only increased replacement costs but also disrupted testing schedules.

Their original supplier's sensors, though accurate, could not withstand the shocks and vibrations typically found in engine test environments. Pt100 sensors are known for their precision but are inherently fragile under such conditions. TC was tasked with solving this problem.

Temperature Measurement Challenges

Although thermocouples are valued for their fast response, high-temperature tolerance and rugged construction, this particular application demanded the precision of Pt100 sensors. However, the sensors had to meet additional challenges, including:

- Withstanding intense vibration within the engine

- Ensuring correct probe positioning for accurate and reliable readings

To address these, it was critical to redesign the sensor all the while considering the unique demands of the application.

Pt100 Sensor Solution

Upon inspection, it became evident that the frequent failures were due to the unsuitable design of the original sensors. Our approach focused on both enhancing the sensor’s construction and understanding the application environment.

Pt100 sensors feature a ceramic sensing element that suspends a coil of platinum wire. High vibration causes these coils to move and touch, leading to erratic readings or permanent damage. In severe cases, the ceramic itself can break, resulting in complete sensor failure.

To resolve this, TC implemented a series of changes:

- Reduced the sheath diameter: This not only improved the sensor's response time but also allowed for a more precise positioning.

- Enhanced internal support: The sensing element was securely held to prevent movement, ensuring durability even under extreme vibrations.

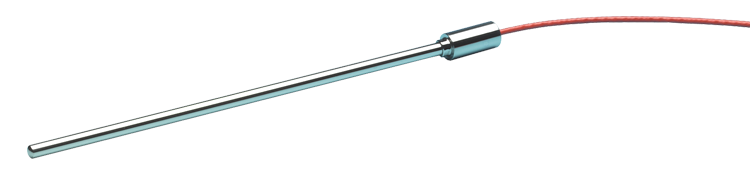

Sensor Type – PT100 Temperature Sensor, High Accuracy 1/10 Din Element, 4 Wire, reduced shock design.

Interested in our Pt100's or Pt1000's? See our range Platinum Resistance Thermometers

Addressing Additional Concerns

To further optimise performance, TC engineers worked closely with the customer to understand the testing setup. This collaborative effort resulted in:

- Repositioning the sensor on the manifold to minimise vibration exposure whilst maintaining the high accuracy measurement requirements at the point of measurement.

- Using a more suitable fitting to secure the sensor firmly, reducing the effects of shock and vibration.

These adjustments significantly extended the sensor’s lifespan while maintaining precision.

Results and Conclusions

The redesigned sensors have delivered exceptional results, with significantly lower failure rates and reduced costs for the customer. The customer was impressed not only with the sensor's performance but also with TC’s 'can-do' approach to solving their problem.

By addressing the root causes and customizing the design, TC provided a durable, accurate and reliable solution that meets the demands of high-vibration environments.

Note: This solution resolved a specific challenge in a particular application. Every situation is different, and your needs may require a different approach. The suitability of any of our products for a particular application is ultimately for the purchaser to determine, as they are best positioned to make that judgment.

These case studies are shared to illustrate how our products have been used successfully, but final product selection should always be based on your specific application requirements, standards, and industry regulations. The suitability of any of our products for a particular application is entirely at the discretion of the purchaser as being the best judge for that particular application.

For application-specific advice, please contact us — one of our engineers will be happy to assist with technical guidance.

Further Reading

Learn more about RTD Pt100 sensors

Explore the unique benefits and technical specifications of RTD Pt100 sensors.

See our range of RTD Pt100 sensors for demanding applications

Discover designs of RTD Pt100's for use in diverse and challenging environments.

Why calibrate RTD's in a UKAS Accredited Laboratory?

Understand the significance of calibration in achieving precise measurements.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia