Pressure and Vacuum Feedthroughs for Thermocouples, Sensors and other single elements

Series PF - Feedthroughs

Request a Quote

Buy Online from TC Direct

Data Sheet

Request a Quote

Buy Online from TC Direct

Data Sheet

TC - Trusted by UK manufacturers, OEMs, and research labs for over 50 years.

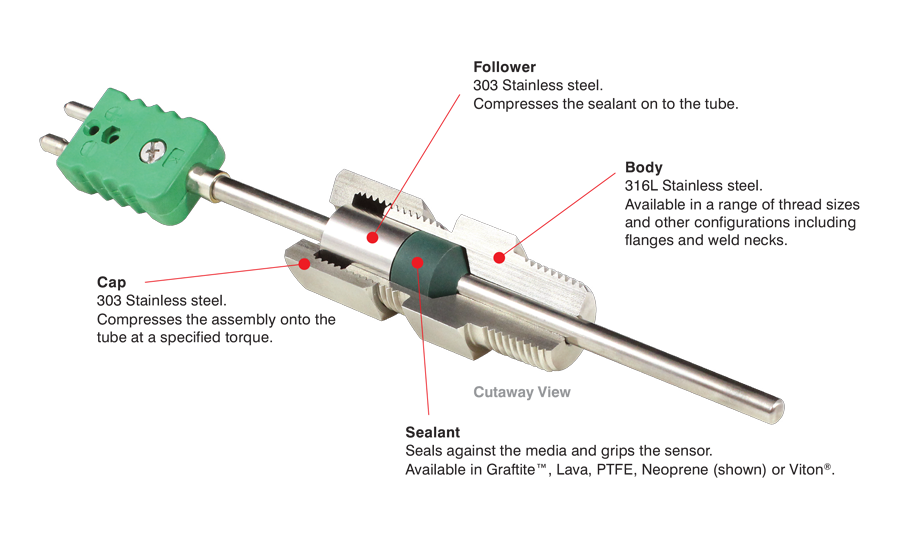

These feed throughs are designed for sealing single elements, usually thermocouple sensors, probes or tubes, where they penetrate a pressure or environmental boundary.

Common applications include sealing sheathed thermocouples and resistance thermometers, small-bore tubes and other types of sensor where they enter a process enclosure.

Series PF feedthroughs seal elements from 0.5mm dia. to 19.05mm (3/4”). There are five body sizes having 1/16”, 1/8”, 1/4”, 1/2” and 3/4” process connections with BSPT (conical gas or DIN 2999 ‘R’) and NPT threads.

Spectite® feedthroughs are designed for ease of assembly and installation. Elements can be adjusted, removed and replaced when not under pressure or vacuum conditions.

Common applications include sealing sheathed thermocouples and resistance thermometers, small-bore tubes and other types of sensor where they enter a process enclosure.

Series PF feedthroughs seal elements from 0.5mm dia. to 19.05mm (3/4”). There are five body sizes having 1/16”, 1/8”, 1/4”, 1/2” and 3/4” process connections with BSPT (conical gas or DIN 2999 ‘R’) and NPT threads.

Spectite® feedthroughs are designed for ease of assembly and installation. Elements can be adjusted, removed and replaced when not under pressure or vacuum conditions.

- Seal on probes, sensors, small-bore tubes and other similar elements

- Immersion length of the element can be easily adjusted

- Five sizes of feedthrough assembly

- Designed for easy installation of single elements 0.5mm to 19.05mm (3/4”) diameter

- Pressure range: Vacuum to 700 bar*

- Temperature range: <-200°C to +870°C*

* Dependent on sealant and fitting selected

- 316L Body (and seat where applicable). Follower and cap in 303 or 304

- Choice of five sealant materials

- Reusable fitting – internal components replaceable

- A large range of feedthroughs is available to buy online

Body Size, Pressure Guide and available Bore Sizes for BSPT, BSPP and NPT Threads2

| Body Size | Size 0 (1/16") | Size 1 (1/8") | Size 2 (1/4") | Size 3 (1/2") | Size 4 (3/4") | Size 5 (1") | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sealant | |||||||||||||||||||||||||||

| G | L | T | G | L | N | T | V | G | L | N | T | V | G | L | N | T | V | G | L | T | V | G | L | T | V | ||

| Element Sizes (dia)3 | The maximum guide pressure value (in bar) at 20°C is shown for each sealant material according to element size1. These ratings are a guide and the suitability of any of the products described herein for a particular application is entirely at the discretion of the purchaser as being the best judge for that particular application. |

||||||||||||||||||||||||||

| inches | mm | ||||||||||||||||||||||||||

| 0.020 | 0.5 | 650 | 550 | 200 | 450 | 550 | 350 | 200 | 350 | ||||||||||||||||||

| 0.032 | 0.8 | ||||||||||||||||||||||||||

| 0.040 | 1.0 | 550 | 700 | 350 | 500 | 700 | |||||||||||||||||||||

| 0.059 | 1.5 | 150 | 150 | 150 | 500 | ||||||||||||||||||||||

| 0.062 | 1.59 | ||||||||||||||||||||||||||

| 0.080 | 2.0 | 450 | 100 | 400 | 450 | 100 | 100 | 550 | 700 | 200 | 200 | ||||||||||||||||

| 0.118 | 3.0 | 550 | 700 | 200 | 200 | 550 | |||||||||||||||||||||

| 0.125 | 3.2 | ||||||||||||||||||||||||||

| 0.157 | 4.0 | 350 | 80 | 550 | 125 | ||||||||||||||||||||||

| 0.177 | 4.5 | ||||||||||||||||||||||||||

| 0.187 | 4.76 | ||||||||||||||||||||||||||

| 0.236 | 6.0 | 450 | 80 | 550 | 500 | 100 | 400 | 400 | 150 | 55 | 150 | ||||||||||||||||

| 0.250 | 6.35 | ||||||||||||||||||||||||||

| 0.312 | 8.0 | 150 | 150 | 450 | 350 | 400 | 250 | ||||||||||||||||||||

| 0.375 | 9.5 | 200 | |||||||||||||||||||||||||

| 0.393 | 10.0 | 80 | 100 | 350 | |||||||||||||||||||||||

| 0.472 | 12.0 | 300 | 75 | 200 | 45 | 40 | |||||||||||||||||||||

| 0.500 | 12.7 | ||||||||||||||||||||||||||

| 0.625 | 15.88 | 200 | 300 | 150 | 100 | 20 | |||||||||||||||||||||

| 0.750 | 19.05 | 30 | |||||||||||||||||||||||||

| 0.839 | 21.3 | ||||||||||||||||||||||||||

| 1.00 | 25.4 | ||||||||||||||||||||||||||

- The guide pressures shown for each type of sealant are at 20°C. Spectite® feedthroughs from TC Ltd. have been designed to provide an efficient seal on the elements and restrain them from moving under pressure and vacuum. It is good installation practice to provide additional, mechanical restraint to the elements when differential pressure exceeds 50% of the feedthrough guide pressure value at 20°C. With an increase in temperature, a reduction in the maximum guide pressure value can be expected. These ratings are a guide and the suitability of any of the products described herein for a particular application is entirely at the discretion of the purchaser as being the best judge for that particular application.

- Other types of process connection are available, see Feedthrough Sizes.

- The element diameters shown are the common sizes routinely demanded for general industrial applications. Other sizes can be supplied between the minimum and maximum diameters shown.

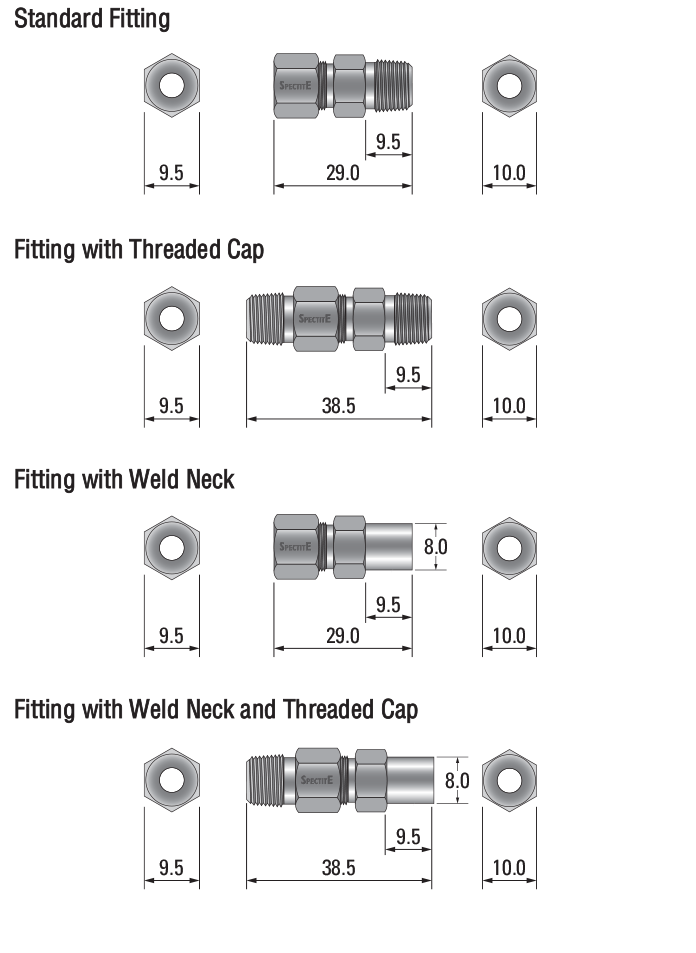

Dimensions

| Size 0 (1/16" Thread or equivalent) | Size 1 (1/8" Thread or equivalent) | Size 2 (1/4" Thread or equivalent) | |

|---|---|---|---|

|

|

|

|

| Size 3 (1/2" Thread or equivalent) | Size 4 (3/4" Thread or equivalent) | Size 5 (1" Thread or equivalent) | |

|

|

|

|

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia