IECEx Approved Pressure and Vacuum Feedthroughs

Series HF - High density, insulated wire sealed tube assemblies

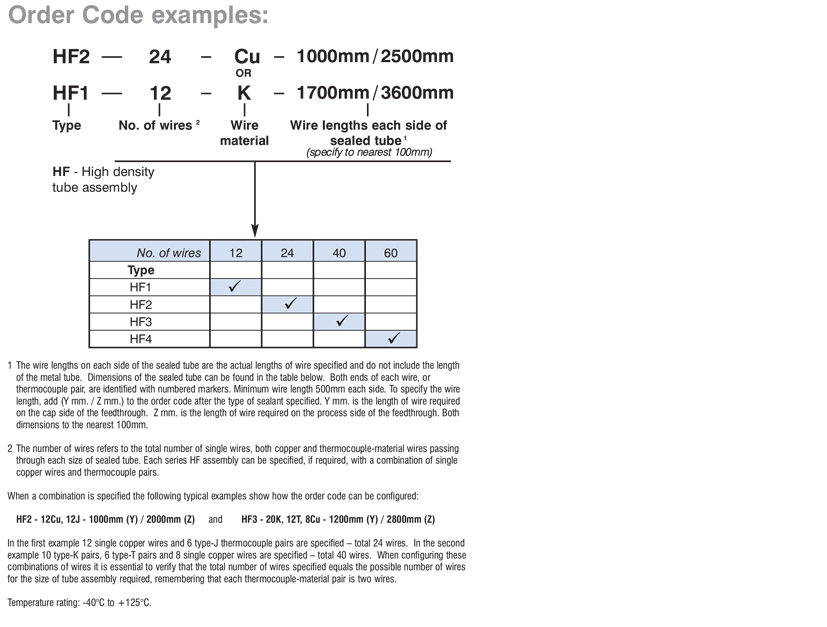

HF assemblies are made up of multiple, insulated, single core copper or thermocouple-material wires which are within a PTFE-lined, swaged stainless steel tube to make high-density, continuous wire, sealed feedthrough tubes. Usually, the tube is then mounted within a PF or MF gland, with customer-specified wire lengths for the inside and outside of a process.

Epoxies and other sealants are not used in the construction of HF feedthroughs. They are suitable for use where outgassing is not permitted. The products are made without sealants or epoxies. They can be used wherever outgassing is not permitted.

Epoxies and other sealants are not used in the construction of HF feedthroughs. They are suitable for use where outgassing is not permitted. The products are made without sealants or epoxies. They can be used wherever outgassing is not permitted.

- Multiple sensor wires pass through one feedthrough, saving time and costs

- IECEx Approved to Ex II 2 GD, Ex d IIC Gb / Ex e IIC Gb, Ex ta IIIC Da (when sealed with appropriate PF/MF fitting)

- Sealed tubes with continuous, multiple, insulated conductors

- Made up of continuous, multiple, insulated wires within sealed tubes

- Sealed 316L Stainless steel tube, without potting, epoxies or glues

- Types K, T, J & N thermocouple-material or copper wires

- 500mA at 100Vdc maximum current rating

- Pressure range: Vacuum to 350 bar with low leak rate

- Pressure ranged from Vacuum to 350 bar with low leak rate

- Size 24AWG copper or thermocouple material wires are used, with either 12, 24, 40 or 60 wires passed through * Dependent on sealant and fitting selected

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia