Thermocouple vs. RTD - Comparing Thermocouples and RTDs

Thermocouples and RTDs (Resistance Temperature Detectors), usually Pt100, are types of temperature sensors widely used in industrial processes and scientific applications.

They are the most popular type of temperature sensor for all kinds of temperature measurement and control applications, with each one having it's own own merits and characteristics. Choosing which one is the most suitable for any given application will largely depend on the accuracy, speed of response, temperature range and durability required.

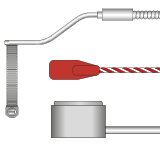

What are Thermocouples?

Thermocouples are temperature sensors made by joining two dissimilar metals at one end, to form a (hot) junction. When this junction changes temperature, it generates a small thermoelectric voltage that is proportional to the temperature difference between the junction and the other end of the thermocouple (the cold junction). This voltage is measured and correlated to determine the temperature. Thermocouples are commonly used in industries like manufacturing, automotive and aerospace due to their durability, wide temperature range, and fast response time. Find out more about how a thermocouple works.

What are RTDs?

RTDs / Pt100s are made using materials whose electrical resistance changes predictably with temperature. The most common RTDs use platinum (Pt100) as a resistive element. As the temperature increases, the resistance of the material increases in a predictable manner. By measuring this resistance change, the temperature can be determined. RTDs provide good accuracy and stability and are often used in applications where precision is essential, such as scientific labs, pharmaceuticals, and HVAC systems. Find out more about how an RTD works.

Do I need an RTD or a Thermocouple?

Whether you choose a thermocouple or an RTD Pt100 sensor depends on the application and measurement requirements (accuracy, speed of response, temperature range etc.) of the user. It is not a case of one being better than the other as both thermocouples and RTD Sensors have their own characteristics and advantages.

We can, however, compare the advantages and limitations of each sensor to try and determine which sensor would be most suited to a particular application:

Temperature Range

Thermocouples have a wider temperature range than RTD Sensors, with some able to measure temperatures up to 1700ºC and beyond. For most industrial applications RTD sensors are limited to 500ºC and more often to 250ºC.

Accuracy

If high accuracy is of most importance, then a Pt100, which is the most common RTD sensor in general use, is the better choice. Even the least accurate Pt100 (Class B) will usually be more accurate than a thermoocouple. Pt100s are available with very high accuracies, 1/10 class elements for example, have an accuracy of ±0.03ºC at 0ºC.

Stability

Thermocouples can drift over time due to chemical changes such as oxidation, whereas measurements from RTD Pt100 sensors are stable and repeatable if the sensor is kept within the temperature range of the RTD sensor.

Response Times

Whilst ever smaller diameters have improved RTD response times considerably, thermocouples, especially with a grounded or exposed junction, are still very much faster in response to changes in temperature.

Durability

Because of the more fragile nature of Pt100 elements, thermocouples are considered more rugged and durable especially for high vibration applications where Pt100 sensors are not suitable. A thermocouple is a simple rugged sensor that can withstand significantly more mechanical abuse than a Pt100.

Cost

Thermocouples are generally less expensive to manufacture and have lower material costs, except for the cabling where thermocouple wires are slightly more expensive than the copper wires used for RTD sensors.

Comparing Thermocouples and RTDs

Temperature Range: Thermocouples perform well in extreme temperature environments, covering a wider range, while RTDs excel in moderate temperature applications requiring high accuracy.

Accuracy and Stability: RTDs are better in terms of accuracy and stability, ideal for applications requiring precise temperature measurements. Thermocouples offer versatility but might compromise accuracy in certain conditions.

Response Time: When fast responses to temperature changes are necessary, thermocouples outperform RTDs due to their rapid response times.

Choosing the Right Temperature Sensor

- Establish the required operating temperature range for your application.

- Determine the level of accuracy required for the temperature measurements.

- Evaluate if the application requires fast responses to temperature fluctuations.

- Compare the initial cost against the long-term stability requirements.

We specialise in the manufacture of thermocouples and RTD Pt100 sensors designed to meet your specific application needs. From surface RTDs or robust mineral insulated thermocouple probes to high temperature ceramic sheathed sensors, our engineers are available on 01895 252222 or via the Live Chat to assist you with design advice.

Need advice on choosing a thermocouple or RTD sensor?

Contact one of our experienced engineers on

01895 252222 or use the Live Chat button.

Advantages and Limitations of RTD Sensors and Thermocouples

| RTD Pt100 | |

|---|---|

| Advantages | Limitations |

|

|

| Thermocouples | |

| Advantages | Limitations |

|

|

Popular Thermocouples

Mineral Insulated Thermocouples Rugged sensors, ideal for most applications. Vast choice of terminations e.g. pot seals, cables, connectors, heads etc.

General Purpose Thermocouples

Rugged sensors, ideal for most applications. Vast choice of terminations e.g. pot seals, cables, connectors, heads etc.

General Purpose Thermocouples

A wide range of thermocouples to suit many applications. Hand held, surface, bayonet, bolt, patch styles etc.

Thermocouples for Surface Measurements

A wide range of thermocouples to suit many applications. Hand held, surface, bayonet, bolt, patch styles etc.

Thermocouples for Surface Measurements

A range of thermocouples to suit various surface temperature measurement applications.

Miniature Thermocouples

A range of thermocouples to suit various surface temperature measurement applications.

Miniature Thermocouples

Ideal for precision temperature measurements where minimal displacement and a fast response is required.

Ideal for precision temperature measurements where minimal displacement and a fast response is required.

Popular RTD Pt100 Sensors

Resistance Thermometers (Pt100, RTD, PRT) -Mineral Insulated

Our most popular style of RTD sensor. Ideal for most applications. Wide choice of terminations e.g. cables, connectors, heads etc.

Resistance Thermometers (Pt100, RTD, PRT) -

Our most popular style of RTD sensor. Ideal for most applications. Wide choice of terminations e.g. cables, connectors, heads etc.

Resistance Thermometers (Pt100, RTD, PRT) -Rigid Stem

Ideal for rigid stem applications or where the sensor is shorter than 50mm, limited to 250°C. Wide choice of terminations

Other Popular Resistance Thermometers (Pt100, RTD, PRT)

Ideal for rigid stem applications or where the sensor is shorter than 50mm, limited to 250°C. Wide choice of terminations

Other Popular Resistance Thermometers (Pt100, RTD, PRT)

A wide range of RTD Sensors to suit many applications. Bayonet, bolt, stator slot, basic element styles etc.

Resistance Thermometers (Pt100, RTD, PRT) -

A wide range of RTD Sensors to suit many applications. Bayonet, bolt, stator slot, basic element styles etc.

Resistance Thermometers (Pt100, RTD, PRT) - for Surface Measurements

A wide range of RTD sensors for surface measurements including self adhesive patch, pipe, magnetic etc.

A wide range of RTD sensors for surface measurements including self adhesive patch, pipe, magnetic etc.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia