Multi Triad and Quad RTD Cable - HR PVC Insulated

RTD Resistance Thermometer Cables

Request a Quote

Buy Online from TC Direct

Data Sheet

TC - Trusted by UK manufacturers, OEMs, and research labs for over 50 years.

|

|

|

||||||||

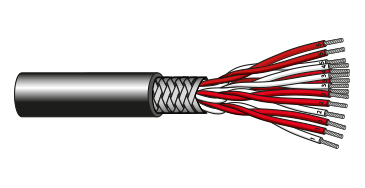

| Multi Triad Cable PVC Insulated Triads of stranded copper conductors. Triads HR PVC insulated. Triads bunched together and numbered. Tinned copper wire braided. HR PVC sheathed overall. |

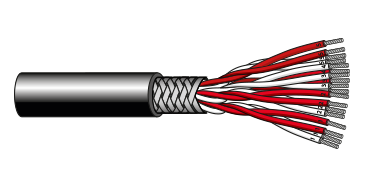

Multi Quad Cable PVC Insulated

Quads of stranded copper conductors. Quads HR PVC insulated. Quads bunched together and numbered. Tinned copper wire braided. HR PVC sheathed overall. |

|||||||||

| Stock Number | MT3705 | MT3710 | MT3715 | MT4705 | MT4710 | MT4715 | ||||

|

Conductor Style | Stranded | Stranded | |||||||

| No. of Strands / Strand Diameter (mm) | 7/0.2 | 7/0.2 | 7/0.2 | 7/0.2 | 7/0.2 | 7/0.2 | ||||

| Total Area (mm2) | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 | 0.22 | ||||

| Total AWG (S = Stranded) | 24S | 24S | 24S | 24S | 24S | 24S | ||||

| Insulation | Heat Resistant PVC | Heat Resistant PVC | ||||||||

|

Number of Cores | 5x3 | 10x3 | 15x3 | 5x4 | 10x4 | 15x4 | |||

| Laid Flat or Twisted | Twisted | Twisted | ||||||||

| Screen | Yes | Yes | ||||||||

|

Insulation | Heat Resistant PVC | Heat Resistant PVC | |||||||

| Insulation Rating (ºC) |

Continuous | -30 to +105 | -30 to +105 | |||||||

| Short Term | —- | — | ||||||||

| Colour Coding | Yes | Yes | ||||||||

| Physical Properties |

Abrasion Resistance | Good | Good | |||||||

| Moisture Resistance | Very Good | Very Good | ||||||||

| Typical Weight (Kg/100m) excl reel |

13 | 22 | 29 | 16 | 27 | 38 | ||||

| Diameter under Armour (mm) | — | — | ||||||||

| Diameter over Armour (mm) | — | — | ||||||||

| Overall Diameter | 10 | 13 | 15 | 11 | 15 | 17 | ||||

| Recommended Cable Gland Ref. | 20S | 20 | 25 | 20S | 25 | 25 | ||||

| Popular Order Codes | MT3705, MT3710 |

MT4705, MT4710 |

||||||||

| Notes All dimensions are approximate |

Rejects electrostatic and electromagnetic interference. Round Section. |

Rejects electrostatic and electromagnetic interference. Round Section. |

||||||||

Frequently Asked Questions

- What is an RTD cable, and why is it important?

An RTD (Resistance Temperature Detector) cable is designed to connect an RTD sensor to measurement equipment. It transmits the resistance signal generated by the RTD sensor, which is then used to accurately measure temperature. The choice of cable material and construction is essential for ensuring the cable can withstand the conditions of your application, such as temperature range, flexibility, and resistance to environmental factors. - What are the different types of RTD cables available?

RTD cables are available in 2, 3, 4, 6 and 8-core variants in a variety of materials, including PVC, PFA, silicone rubber, and fibreglass. Each material is suited for different temperature ranges and environmental conditions. For example, silicone rubber is flexible and ideal for low to medium-temperature applications, while PFA offers higher temperature resistance and is suitable for more demanding environments. - How do I choose the right RTD cable for my application?

Choosing the right RTD cable depends on factors like temperature range, flexibility, and environmental resistance. For higher temperature applications, materials like PFA (250ºC) or fibreglass (480ºC) are ideal, whereas for general-purpose or lower-temperature use, PVC (105ºC) or silicone rubber (200ºC) cables may be more suitable. Please check the specifications of each cable to ensure it matches the needs of your application. Our engineers are also available to provide tailored advice.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia