High Temperature Thermocouple with 316 Stainless Steel Head

High Temperature Metal Sheathed Thermocouples (Type 27)

Request a Quote

Data Sheet

Request a Quote

Data Sheet

TC - Trusted by UK manufacturers, OEMs, and research labs for over 50 years.

These high temperature thermocouples are used in applications where other thermocouples would fail due to excessive heat or severe environments. Utilising specialist exotic sheath materials such as Platinum 10% Rhodium, Molybdenum and Tantalum they can be used in service temperatures up to 2300°C. The combination of conductor, insulation material and sheath must be carefully selected to suit your process environment, service temperature and installation requirements (i.e. whether the probe is flexible or not). Our experienced sales team are on hand to assist where needed, so please do not hesitate to contact us if help is required.

- Typically used with high temperature thermocouple types R, S, B, C and D

- Temperatures up to 2200°C (continuous use) or 2300°C (short term use)

- Semi-Rigid (mineral insulated) and Rigid (tube) styles available

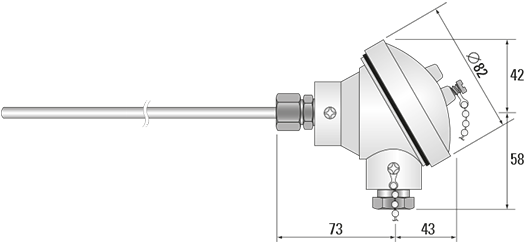

- Terminated in a 316 Stainless Steel standard terminal head

- Calibration service for oxidizing and inert environments is available up to 1600°C

| Code | Sheath Material | Operational Properties | MI (Semi-Rigid) Tube (Rigid) |

Insulation Material | Thermocouple Types | Available Sheath Diameters (mm) | Max. Continuous Temperature |

| 600 | Inconel 600® |

Suitable for use in inert, vacuum and oxidizing environments.

Minimum bend radius: 5 x sheath diameter. Not recommended for use above 800°C in oxidising atmospheres. Do not use in sulphur bearing atmospheres above 550°C. |

Semi-Rigid | MgO | R, S and B | 1.0mm, 1.5mm, 3.0mm, 3.2mm, 4.8mm, 6.0mm and 6.4mm | 1175°C |

| 600T | Inconel 600® | As above. Do not bend. | Rigid | Al2O3 | R, S and B | 3.0mm, 3.2mm, 4.8mm, 6.0mm and 6.4mm | 1175°C |

| P10R | Platinum 10% Rhodium | Suitable for use in inert and oxidizing environments. Minimum bend radius: 10 x sheath diameter. |

Semi-Rigid | MgO | R, S and B | 1.0mm, 1.5mm and 1.6mm | 1550°C |

| TAN | Tantalum | Suitable for use in inert and vacuum environments. Minimum bend radius: 5 x sheath diameter. |

Semi-Rigid | MgO, Al2O3, HfO2 | R, S, B, C and D | 1.0mm, 1.5mm, 1.6mm, 3.0mm and 3.2mm | 2200°C |

| NIO | Niobium 1% Zirconium | Suitable for use in inert and vacuum environments.

Minimum bend radius: 10 x sheath diameter. |

Semi-Rigid | MgO, Al2O3, HfO2 | R, S, B, C and D | 1.6mm and 3.2mm | 2200°C |

| MOL | Molybdenum | Suitable for use in inert, vacuum and reducing environments.

Do not bend. |

Rigid | MgO, Al2O3, HfO2 | R, S, B, C and D | 1.5mm, 1.6mm, 3.0mm,

3.2mm, 4.8mm, 6.0mm and 6.4mm |

2000°C |

| CMOL | Coated Molybdenum | Suitable for use in inert and oxidizing environments.

Do not bend. |

Rigid | MgO, Al2O3, HfO2 | C and D | 1.5mm, 1.6mm, 3.0mm, 3.2mm and 6.4mm | 1600°C |

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia