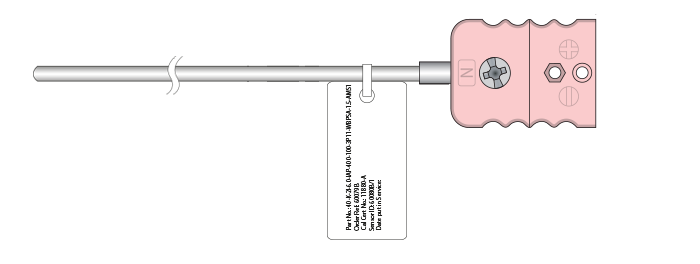

Heat Treatment Thermocouple with Standard Socket

AMS2750 Approved Thermocouples for Heat Treatment

Request a Quote

Data Sheet

Request a Quote

Data Sheet

TC - Trusted by UK manufacturers, OEMs, and research labs for over 50 years.

Calibrated Mineral Insulated Thermocouples

Our range of AMS2750 NADCAP, BAC5621 or CQI-9 compliant mineral insulated thermocouples are designed to meet the high quality and accuracies demanded for heat treatment applications within the Aerospace industry. Through careful material selection and a comprehensive calibration program in our ISO17025 UKAS accredited laboratory, we can offer a wide range of sheath diameters and materials from stock with quick manufacture times. Their semi rigid construction allows them to be bent and formed to suit particular applications without impairing performance.

Our range of AMS2750 NADCAP, BAC5621 or CQI-9 compliant mineral insulated thermocouples are designed to meet the high quality and accuracies demanded for heat treatment applications within the Aerospace industry. Through careful material selection and a comprehensive calibration program in our ISO17025 UKAS accredited laboratory, we can offer a wide range of sheath diameters and materials from stock with quick manufacture times. Their semi rigid construction allows them to be bent and formed to suit particular applications without impairing performance.

- Calibrated in line with AMS 2750 NADCAP, BAC5621 or

CQI-9 requirements - Suitable for use in Temperature Uniformity Surveys (TUS), System Accuracy Tests (SAT), Control Recording and Monitoring and Load sensors

- Batch calibration certificate supplied as standard

- Sensors are individually tagged and numbered for full traceability

- Available in thermocouple types N, K, T and J

- Wide range of sheath diameters and materials

Calibration Accuracies:

| Code | Standard | Accuracy Supplied | Permitted Applications | Certification |

| AMS1 | AMS2750 | ±1.1ºC or 0.4% of reading (whichever is greater), end to end deviation of material batch no greater than 1.1ºC | Temperature Uniformity Survey (TUS) System Accuracy Test (SAT) Control, Monitoring & Recording (Class 1 & 2) |

An in-house 3-page report for the start/end of batch from 0-1200ºC with all the information NADCAP auditors require (please refer to the Calibration Details section for a detailed explanation). Please note: UKAS calibration is available on request. |

| BAC2 | BAC5621 | ±1.1ºC <538ºC or 0.4% of reading >538ºC, end to end deviation of material batch no greater than 0.6ºC | Secondary/Field Test Sensor | |

| CQI1 | CQI-9 | ±1.1ºC or 0.4% of reading (whichever is greater), end to end deviation of material batch no greater than 1.1ºC | Temperature Uniformity Survey (TUS) System Accuracy Test (SAT) Control, Monitoring & Recording (Class 1 & 2) Load |

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia