Type N Thermocouple - technical Information

Type N - Nickel-Chromium-Silicon vs Nickel-Silicon, IEC 60584-1

Thermocouple Type N, is a relatively new thermocouple type and was billed as a replacement for the Type K thermocouple (the most common in industrial use), but without its drawbacks - Type N (Nicrosil-Nisil) exhibits a much greater resistance to oxidation-related drift at high temperatures than its rival, and to the other common instabilities of Type K in particular, but also the other base metal thermocouples to a degree. It can thus handle higher temperatures than Type K (1,280°C, and higher for short periods).

Type N Thermocouples - Typical Constructions and Styles

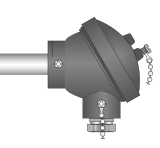

Type N Mineral InsulatedThermocouples

Rugged sensors, ideal for most applications. Vast choice of terminations e.g. pot seals, cables, connectors, heads etc.

Type N Thermocouples for use

in Heat Treatment Applications

Rugged sensors, ideal for most applications. Vast choice of terminations e.g. pot seals, cables, connectors, heads etc.

Type N Thermocouples for use

in Heat Treatment Applications

Calibrated thermocouples designed to meet the high quality and accuracies demanded for heat treatment applications within the Aerospace industry

Type N Miniature

Calibrated thermocouples designed to meet the high quality and accuracies demanded for heat treatment applications within the Aerospace industry

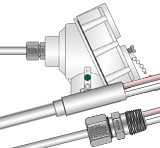

Type N MiniatureThermocouples

Ideal for precision temperature measurements where minimal displacement and a fast response is required.

Type N Heavy Duty

Ideal for precision temperature measurements where minimal displacement and a fast response is required.

Type N Heavy DutyThermocouples

For industrial applications such as furnaces, kilns, ovens, boliers, flues etc. Many types of sheath material available.

General Purpose

For industrial applications such as furnaces, kilns, ovens, boliers, flues etc. Many types of sheath material available.

General PurposeType N Thermocouples

A wide range of thermocouples to suit many applications. Hand held, surface, bayonet, bolt, patch styles etc.

ATEX/IECEx Approved

A wide range of thermocouples to suit many applications. Hand held, surface, bayonet, bolt, patch styles etc.

ATEX/IECEx ApprovedType N Thermocouples

A large range of thermocouples with a variety of terminations such as pot seal, terminal heads etc.

A large range of thermocouples with a variety of terminations such as pot seal, terminal heads etc.

Explore our in-depth Thermocouple & RTD Guide — a technical resource developed for engineers and specifiers. Covers sensor selection, installation practices, standards and tolerances, colour codes, wiring configurations, sensor theory and more.

Oxidation resistance is superior in Type N because of the combination of a higher level of chromium and silicon in the positive Nicrosil conductor. Similarly, a higher level of silicon and magnesium in the negative Nisil conductor form a protective diffusion barrier. Type N also shows much improved repeatability in the 300°C to 500°C range where Type K’s stability is more lacking (due to hysteresis induced by magnetic and/or structural inhomogeneities). High levels of chromium in the NP conductor and silicon in the NN conductor provide improved magnetic stability. Beyond this, it does not suffer from other long term drift problems associated with transmutation of the high vapour pressure elements in mineral insulated thermocouple assemblies (mainly manganese and aluminium from the KN wire through the magnesium oxide insulant to the KP wire). Transmutation is virtually eliminated since the conductors contain only traces of manganese and aluminium. Finally, since manganese, aluminium and copper are not used in the NN conductor, stability against nuclear bombardment is much better.

Standardised in 1986 as BS EN 60584-1 Part 8 and subsequently published in IEC 60584, this relative newcomer to thermocouple thermometry has even been said to make all other base metal thermocouples (E, J, K and T) obsolete. It can be said to provide many of the rare metal thermocouple characteristics, but at base metal costs. In fact, up to a maximum continuous temperature of 1,280°C, depending on service conditions, it can be used in place of Type R and S thermocouples (which are between 10 and 20 times the price).

Although adoption of this thermocouple type was slower than anticipated, it is now seeing ever greater use. There is no doubt that it is a fundamentally better thermocouple than its base metal rivals.

Type N - Technical Data

| Conductor Combination | Approximate generated EMF change in µV per ºC change (referenced to 0ºC) at: |

Approximate Working Temperature Range |

Thermocouple Output Tolerances to IEC 60584-1 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| + Leg | - Leg | 100ºC | 500ºC | 1000ºC | Continuous | Short Term | Type | Class 1 | Class 2 | Class 3 |

| NICKEL - CHROMIUM -SILICON Also known as: Nicrosil | NICKEL - SILICON - MAGNESIUM Also known as: Nisil |

30 | 38 | 39 | 0 to +1150ºC | -270 to +1300ºC | Temperature Range Tolerance Value Temperature Range Tolerance Value |

–40°C to +375°C ±1.5°C 375°C to 1000°C ±0.004⋅ |t| |

–40°C to +333°C ±2.5°C 333°C to 1200°C ±0.0075⋅ |t| |

–167°C to +40°C ±2.5°C –200°C to –167°C ±0.015⋅ |t| |

2. Thermocouple materials are normally supplied to meet the tolerances specified in the table for temperatures above –40 deg C. These materials however, may not fall within the tolerances for low temperatures given under Class 3 for Types T, E and K thermocouples. If thermocouples are required to meet limits of Class 3, as well as those of Class 1 and/or Class 2, the purchaser should state this, as selection of materials is usually required.

3. The maximum temperature rating is dependant upon construction, size and atmospheric conditions. A more detailed guide for the maximum temperature ratings of mineral insulated thermocouples can be found here.

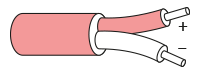

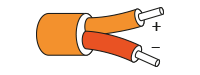

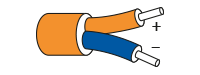

Cable Colour Codes for N Type Thermocouples

| International Colour Code to IEC 60584-3 | US colour code to ASTM E 230 | Redundant national colour coding for thermocouple cables | ||

|---|---|---|---|---|

| BS 1843 | DIN 43714 | NFC 42324 | ||

|

|

| – | – |

Frequently Asked Questions

- What is a thermocouple and how does it work?

A thermocouple is a type of temperature sensor that generates a voltage when two different metals are joined at one end and exposed to a temperature difference between the "hot" junction (where the temperature is measured) and the "cold" junction (the reference point). This voltage is then measured to determine the temperature at the hot junction. - How do I choose the right thermocouple for my application?

The ideal thermocouple depends on factors such as temperature range, accuracy, termination type, mounting requirements and environmental conditions. We offer a variety of thermocouples with different sheath materials, constructions, terminations, and temperature ratings to meet your needs. If you need specific advice, our engineers are happy to assist! - What is the maximum temperature rating of your thermocouples?

Our thermocouples are designed to handle a wide range of temperatures with some mineral insulated thermocouples able to withstand temperatures up to 1400ºC and ceramic sheathed thermocouples going even higher to 1600ºC. Each product listing includes the maximum temperature rating, so you can choose the best thermocouple for your application.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia