Dual Display Temperature and Process Controllers

Temperature Controllers

Request a Quote

Buy Online from TC Direct

Request a Quote

Buy Online from TC Direct

TC - Trusted by UK manufacturers, OEMs, and research labs for over 50 years.

Related Products

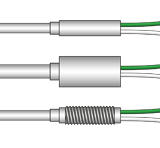

Mineral Insulated Thermocoupleswith pot seal

Mineral Insulated

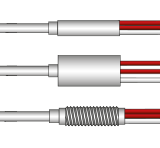

Mineral InsulatedResistance Thermometers

with pot seal

Control

The FB400/900 feature BrilliantTM PID with autotuning and a choice of control algorithm for fixed setpoint, ramping setpoint and cascade control applications.

Measurement Accuracy

The FB400 and FB900 feature a measurement accuracy of better than ±0.1% of span.

Sampling Time

Selectable input sampling times of 50, 100 and 250mseconds enable the FB range to be used for a wide range of applications from fast pressure or flow control to precision temperature control.

Selectable Control Type

The control type may be configured by the user for heat, cool, heat/cool and valve motor drive.

Enhanced Autotuning

In addition to the standard ‘single shot’ autotuning a fast start up autotuning function is included which may be used at process start up or continuously depending on the application.

Inputs

A wide range of thermocouple, resistance thermometer, current and voltage inputs are user selectable.

Outputs

Relay, SSR, current, voltage and open collector outputs are available.

The FB400/900 feature BrilliantTM PID with autotuning and a choice of control algorithm for fixed setpoint, ramping setpoint and cascade control applications.

Measurement Accuracy

The FB400 and FB900 feature a measurement accuracy of better than ±0.1% of span.

Sampling Time

Selectable input sampling times of 50, 100 and 250mseconds enable the FB range to be used for a wide range of applications from fast pressure or flow control to precision temperature control.

Selectable Control Type

The control type may be configured by the user for heat, cool, heat/cool and valve motor drive.

Enhanced Autotuning

In addition to the standard ‘single shot’ autotuning a fast start up autotuning function is included which may be used at process start up or continuously depending on the application.

Inputs

A wide range of thermocouple, resistance thermometer, current and voltage inputs are user selectable.

Outputs

Relay, SSR, current, voltage and open collector outputs are available.

Communications

ANSI and Modbus communications are available for RS232, 485 and 422. A second RS485 communication port may be used for precise inter-controller communication for the following applications: automatic temperature rise where temperature rate of rise will be automatically controlled to avoid uneven heating rates, temperature ratio setting for master/slave remote setpoint applications and cascade control.

Memory Area Location of Set and other Values

The FB range can store up to eight groups of setpoint, alarm values and PID control terms. Selection of each group may be accessed from the front panel or remotely using digital input contacts or communication.

Programme Control

By linking memory areas and using the setpoint ramping and soak time parameters it is possible to use the FB400/900 as a programmer controller.

Power Feed Forward (PFF)

This option constantly monitors the electrical load through a dedicated transformer. The instruments control output is then automatically adjusted to compensate for fluctuations in the power supply.

ANSI and Modbus communications are available for RS232, 485 and 422. A second RS485 communication port may be used for precise inter-controller communication for the following applications: automatic temperature rise where temperature rate of rise will be automatically controlled to avoid uneven heating rates, temperature ratio setting for master/slave remote setpoint applications and cascade control.

Memory Area Location of Set and other Values

The FB range can store up to eight groups of setpoint, alarm values and PID control terms. Selection of each group may be accessed from the front panel or remotely using digital input contacts or communication.

Programme Control

By linking memory areas and using the setpoint ramping and soak time parameters it is possible to use the FB400/900 as a programmer controller.

Power Feed Forward (PFF)

This option constantly monitors the electrical load through a dedicated transformer. The instruments control output is then automatically adjusted to compensate for fluctuations in the power supply.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia